It is applied to machining big gears of high precision for energy sources, transportation, mine, electric power and heavy-machinery. It can be used to process kinds of spur and helical gears, small tapered gear, crowed gear, worm gear, etc. The individual indexing internal gear can be processed if you adopt the replaceable part of internal gear milling head.

The guideway for linear movement adopt imported rolling guideway block with inlay steel guide of high precision. Feeding system uses preload ball screws with imported linear grating of high precision to ensure the precision of drive and feeding.

|

Specifications

|

YK31250

|

|

Max.workpiece diameter(mm)

|

2500

|

|

Max.module(mm)

|

25

|

|

Max.face width(mm)

|

800

|

|

Max.helical angle

|

±45°

|

|

Rotate speed of hob(r/min )

|

20~250

|

|

Max.diameter of hob(mm)

|

450

|

|

Max.length of hob(mm)

|

700

|

|

Taper bore of main spindle

|

BT60

|

|

Distance from spindle center to worktable center(mm)

|

200~1500

|

|

Distance from rotary center of tool rest to worktable surface(mm)

|

700~1900

|

|

Max.load bearing of worktable(Kg)

|

40000

|

|

Worktable Diameter(mm)

|

1850

|

|

Bore of the worktable(mm)

|

600

|

|

Worktable rotary speed(r/min)

|

0~10

|

|

Radial feed speed(mm/min)

|

0~3000

|

|

Axial feed speed(mm/min)

|

0~3000

|

|

Total power(kw)

|

100

|

|

Total weight(Kg) approx.

|

45000

|

Note: The above mentioned parameters for your reference only. If have (any requires) Please contact us.

|

Standard Accessories

|

|

Numerical control system: 840D Siemens

|

|

One set hydraulic device: Outside

|

|

One set cooling and chip conveyor: Outside

|

|

Centralized auto-lubrication: By Inrermittent

|

|

Electrical cabinet: Outside

|

|

Full cover

|

|

Accessories box

|

|

Machine sizing block

|

|

Optional Accessories

|

|

Fixture

|

|

Special cutter adaptor

|

|

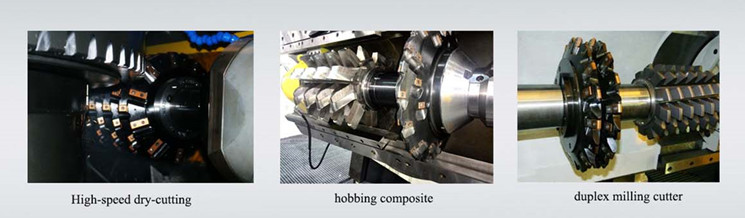

Milling tools

|

|

Internal milling head

|